If you reach BLD then you need to address inlet charge temps (intercooling, or water/[eth|meth]anol injection), compression (static or dynamic), or easiest of all up the Octane of your base fuel.

If you reach peak torque, congratulations you've won! Now repeat it across the entire load and RPM map

As for maximum EGTs, remember that aluminium melts at around ~660deg, your cylinder temperatures during combustion are always much higher than EGT (unless you've massively retarded the ignition) but they only see the peak temps for short time, as the incoming charge temps are (if intercooled correctly) close to ambient, which cools the cylinder massively. Plus you have valve seats and a water jacket to help wick a lot of the excess temps away.

So, where does that leave us? Well as stated before there is no definative EGT value, Scott has posted to spot on rules of thumb, I've seen higher EGTs and Idle, and lower at peak. But I've not seen lower at idle and higher at WOT TBH!

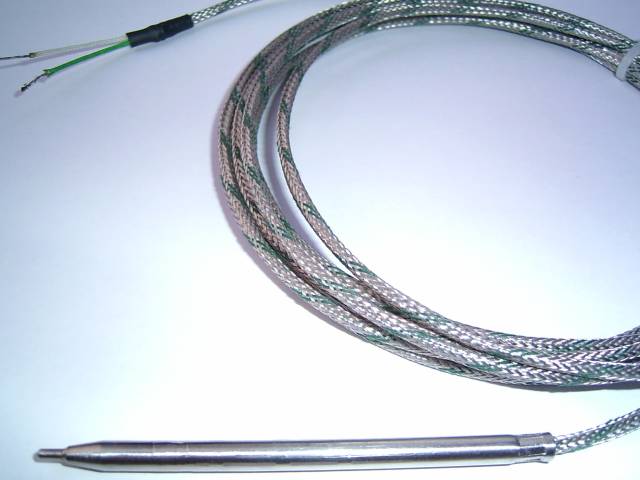

Really for EGT you need to place a thermocouple in or close to the inlet of the turbine housing, then you find that you have another issue to solve - the first is to get fast response you need a thin <3mm thick thermocouple which will have a limited expectancy as it will slowly ionise disolve. If you use a thick >5mm probe/Thermocouple you'll have longevity but not get the speed required for a true reading. There is a 3rd way which is a mix of both and its what we use on our systems:

Which provides speed and longevity.