Niges MK2 Golf Track car build in 5 weeks.. MASSIVE Thread !

A little post Easter update.

The car performed really well,only a few issues. The new gearbox ratios are fabulous. I`m getting 6500rpm (130mph) at the SX crest when I`ve had a good exit from FP. Thats just about perfect and I`m really pleased I swapped it. The other one would have been useless and annoyed me.

Ran fine on Parada Spec2`s in the cold

Found this wire had broken, the car appeared to be running fine, but I resoldered it anyway.

Emptied the oil-catch bottle. This is after 70 laps of the ring, so I don

The car performed really well,only a few issues. The new gearbox ratios are fabulous. I`m getting 6500rpm (130mph) at the SX crest when I`ve had a good exit from FP. Thats just about perfect and I`m really pleased I swapped it. The other one would have been useless and annoyed me.

Ran fine on Parada Spec2`s in the cold

Found this wire had broken, the car appeared to be running fine, but I resoldered it anyway.

Emptied the oil-catch bottle. This is after 70 laps of the ring, so I don

I`d forgotten to update this thread.. whoops.

Thought I`d get this up to date... Most is a copy from my summer trip report but it is pretty much up to date now.

Fitted a couple of spring clips to the inside of the boot to keep my yellow flag in place, ready for quick retrieval if needed.

Moved the oil cooler to the `summer` position. If I run it there in winter, it is too efficient, its a 19-row cooler and works too well, hence the `behind the bumper

Thought I`d get this up to date... Most is a copy from my summer trip report but it is pretty much up to date now.

Fitted a couple of spring clips to the inside of the boot to keep my yellow flag in place, ready for quick retrieval if needed.

Moved the oil cooler to the `summer` position. If I run it there in winter, it is too efficient, its a 19-row cooler and works too well, hence the `behind the bumper

-

Charlie Chalk

- Posts: 44

- Joined: Thu Sep 11, 2008 11:23 am

- Location: London

Fantastic car and driver.

Went for a lap around the ring with Nige in this and he certainly knows the place very well.

It was most noticeable going flat over the crest at flugplatz and staying flat through the two right handers. Funny how the track changes completely in different cars.

Over that jump at pflanzgarten he is also particularly impressive, considering that was the scene of his famous written off golf last year

Great trip and great company - see you on the 12th Oct mate :thumb:

Went for a lap around the ring with Nige in this and he certainly knows the place very well.

It was most noticeable going flat over the crest at flugplatz and staying flat through the two right handers. Funny how the track changes completely in different cars.

Over that jump at pflanzgarten he is also particularly impressive, considering that was the scene of his famous written off golf last year

Great trip and great company - see you on the 12th Oct mate :thumb:

AH, I forgot to update this again.  Quite a bit to follow.... :-D

Quite a bit to follow.... :-D

OCT 2008

Gave the Golf a service last week. Oil changed and coolant flush, then replaced with strong antifreeze mix for the winter.

I`d bought a new set of braided hoses when the front had started chafing away in the summer, so it seemed sensible to fit the remaining new ones and keep the `old` ones as spares.

Took the opportunity to move the rear Tee where the pipes split to the back brakes. The original Tee was under the car and then the pipes ran to each caliper, deciding that minimising the amount of pipe outside the car would be a good thing, in terms of protection and keeping at away from my wayward exhaust, I replaced the 2 rear `runs`, mounted the Tee in the cabin and spiral wrapped the pipes in the car for added protection.

I also fitted replacement front discs and new front pads. Once all the hoses/ pipes were changed, I flushed the system with new 5.1 brake fluid.

I changed the rear wheel bearings, the nearside one had managed to last the enitre summer, so it seemed prudent to change it. I have always struggled to get the centre nut just tight enough and Chris Slator who had popped over to help gave me a great tip to get it right.

Rebuild the bearing and fit a wheel, leave off the split pin, castle nut and cover. Now spin the wheel, tighten the centre nut.

By `wobbling` the wheel from the very edge (usually with both hands) you can feel the tiniest movement in the bearing and tighted the centre nut so it is JUST tight enough, then refit the castle cover, split pin and cap. It worked really well and was a fabulous tip :thumb:

Next job was to fit the rear vents to try and get a bit more airflowing through the car. Bought a hole cutter from Ebay, they don`t sell a hole saw the correct size.

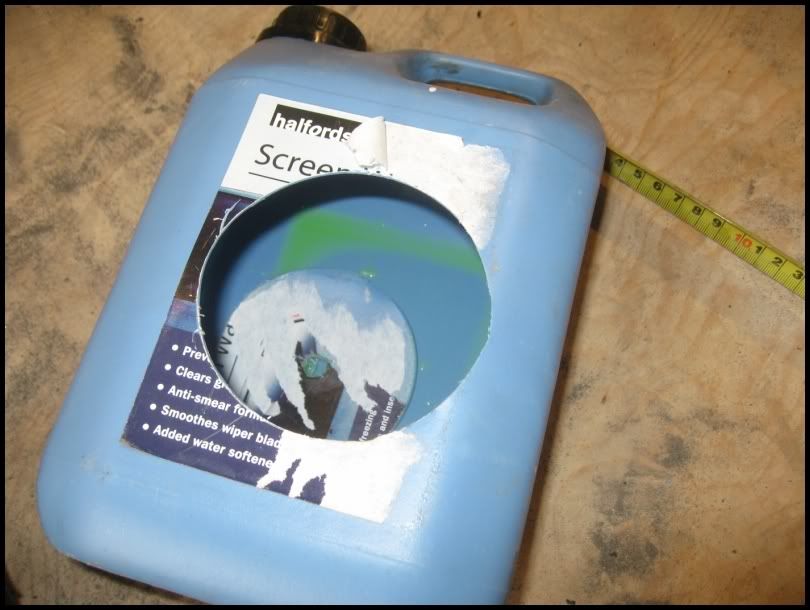

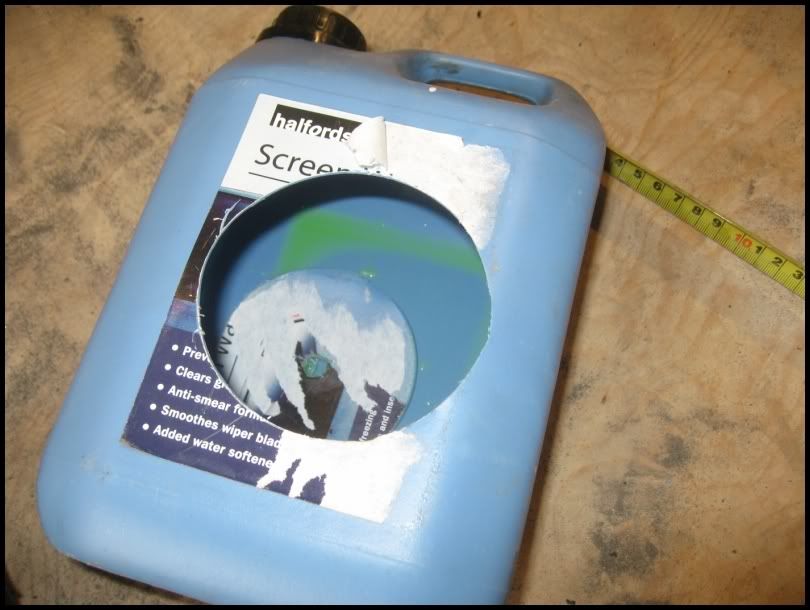

Made a test hole in an old screenwash container to check it was the right size for the vent.

Used the cut-out from the container to position where I wanted the vents.

Drilled a hole in my windows !!! Was very careful (obviously) but as the cutter was new and sharp, it was easy.

Was very careful (obviously) but as the cutter was new and sharp, it was easy.

Fitted the vent. Closed

Open

Not sure how much they will help, but they have to be better than nothing at all :huh:

Next job was raising the gearlever. Bent 2 pieces of tube

Cut a piece of plate to weld over the `hole` where the original mechanisom comes throught he floor of the car

Tacking it into place then fully welding and grinding it smooth

Tack welded the 2 `sides` into position

Checked gearlever position at new height (spot on)

Welded a horizontal support between the 2 pieces and then welded some nuts to the frame. Used Hex screws to secure the shifter mechanism to the new frame, only had time to spray with primer as I was going to Elvington the next morning..

It moves the gearlever to a far more convenient height, it falls naturally to hand when changing gear and doesn`t foul the handbrake. A very worthwhile `mod` for a track Golf I reckon [:)]

OCT 2008

Gave the Golf a service last week. Oil changed and coolant flush, then replaced with strong antifreeze mix for the winter.

I`d bought a new set of braided hoses when the front had started chafing away in the summer, so it seemed sensible to fit the remaining new ones and keep the `old` ones as spares.

Took the opportunity to move the rear Tee where the pipes split to the back brakes. The original Tee was under the car and then the pipes ran to each caliper, deciding that minimising the amount of pipe outside the car would be a good thing, in terms of protection and keeping at away from my wayward exhaust, I replaced the 2 rear `runs`, mounted the Tee in the cabin and spiral wrapped the pipes in the car for added protection.

I also fitted replacement front discs and new front pads. Once all the hoses/ pipes were changed, I flushed the system with new 5.1 brake fluid.

I changed the rear wheel bearings, the nearside one had managed to last the enitre summer, so it seemed prudent to change it. I have always struggled to get the centre nut just tight enough and Chris Slator who had popped over to help gave me a great tip to get it right.

Rebuild the bearing and fit a wheel, leave off the split pin, castle nut and cover. Now spin the wheel, tighten the centre nut.

By `wobbling` the wheel from the very edge (usually with both hands) you can feel the tiniest movement in the bearing and tighted the centre nut so it is JUST tight enough, then refit the castle cover, split pin and cap. It worked really well and was a fabulous tip :thumb:

Next job was to fit the rear vents to try and get a bit more airflowing through the car. Bought a hole cutter from Ebay, they don`t sell a hole saw the correct size.

Made a test hole in an old screenwash container to check it was the right size for the vent.

Used the cut-out from the container to position where I wanted the vents.

Drilled a hole in my windows !!!

Fitted the vent. Closed

Open

Not sure how much they will help, but they have to be better than nothing at all :huh:

Next job was raising the gearlever. Bent 2 pieces of tube

Cut a piece of plate to weld over the `hole` where the original mechanisom comes throught he floor of the car

Tacking it into place then fully welding and grinding it smooth

Tack welded the 2 `sides` into position

Checked gearlever position at new height (spot on)

Welded a horizontal support between the 2 pieces and then welded some nuts to the frame. Used Hex screws to secure the shifter mechanism to the new frame, only had time to spray with primer as I was going to Elvington the next morning..

It moves the gearlever to a far more convenient height, it falls naturally to hand when changing gear and doesn`t foul the handbrake. A very worthwhile `mod` for a track Golf I reckon [:)]